Fasteners and Machining: Key to Effective and Reliable Production

Fasteners and Machining: Key to Effective and Reliable Production

Blog Article

Unveiling the Complexities of Bolts and Machining Procedures for Optimal Performance

In the realm of engineering and manufacturing, the option of bolts and the ins and outs of machining procedures play a crucial role in establishing the ultimate performance and toughness of an item. From the seemingly uncomplicated task of selecting the ideal kind of fastener to the complex accuracy machining methods employed, every step in this procedure demands precise attention to detail. As we start this expedition into the globe of bolts and machining, we will certainly uncover the refined yet crucial variables that can substantially impact the performance and quality of the end product, dropping light on the usually forgotten elements that can make all the distinction in accomplishing optimum performance.

Importance of Appropriate Fastener Selection

Selecting the ideal fasteners is vital in guaranteeing the structural honesty and longevity of any type of mechanical setting up. Bolts play a fundamental duty in holding elements with each other safely, with the appropriate choice contributing significantly to the total performance and dependability of the assembly. When picking bolts, elements such as product compatibility, ecological problems, load-bearing capability, and simplicity of installation have to be thoroughly considered to guarantee ideal performance.

Incorrect bolt option can lead to a series of concerns, consisting of helping to loosen, rust, and also structural failing. Utilizing bolts that are not fit to the particular demands of the assembly can endanger its functionality and position safety threats. Consequently, engineers and designers have to diligently evaluate the application requires and select bolts that fulfill or exceed the needed standards and requirements.

In addition, the correct bolt selection procedure entails examining the joint layout, expected lots, resonance degrees, and possible thermal expansion or contraction to ensure that the selected bolts can endure the operating conditions efficiently. By focusing on correct bolt choice, makers can improve the quality, sturdiness, and efficiency of their mechanical assemblies.

Types and Characteristics of Bolts

An essential facet of mechanical assemblies depends on comprehending the diverse kinds and distinct features of fasteners utilized in numerous commercial applications. Bolts are critical components that hold frameworks together, making certain security and capability. There is a wide variety of fasteners available, each made for details functions based upon the application requirements. Common sorts of fasteners consist of screws, bolts, nuts, pins, rivets, and washing machines.

Screws are threaded bolts that are commonly utilized to sign up with two or more elements together. Nuts are internally threaded bolts that mate with screws to hold elements together. Washing machines are slim plates that distribute the tons of a fastener, avoiding damage to the material being attached.

Understanding the characteristics of each sort of fastener is essential for choosing the ideal one for a certain application, guaranteeing optimum performance and dependability of the mechanical setting up. Fasteners and Machining.

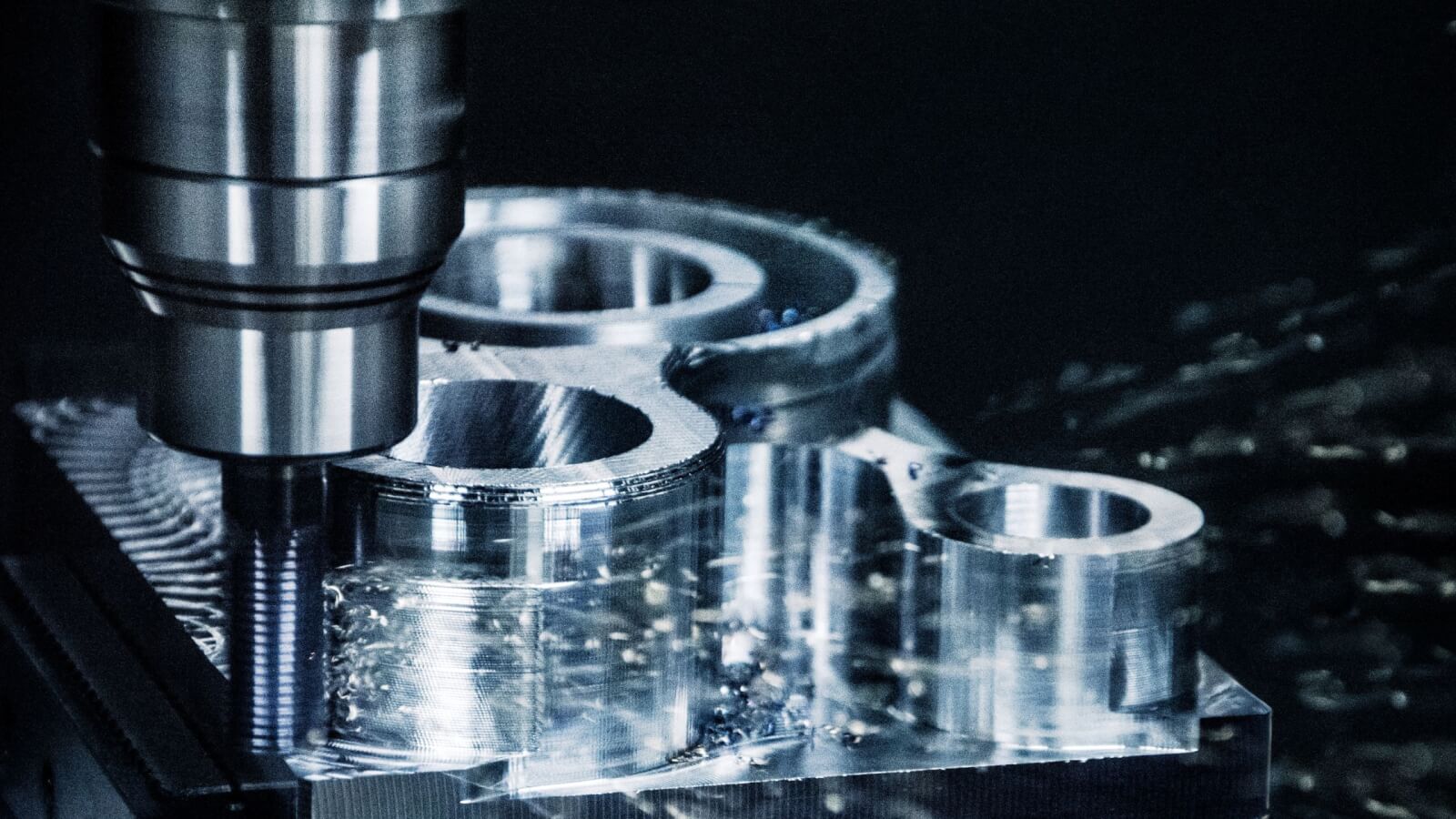

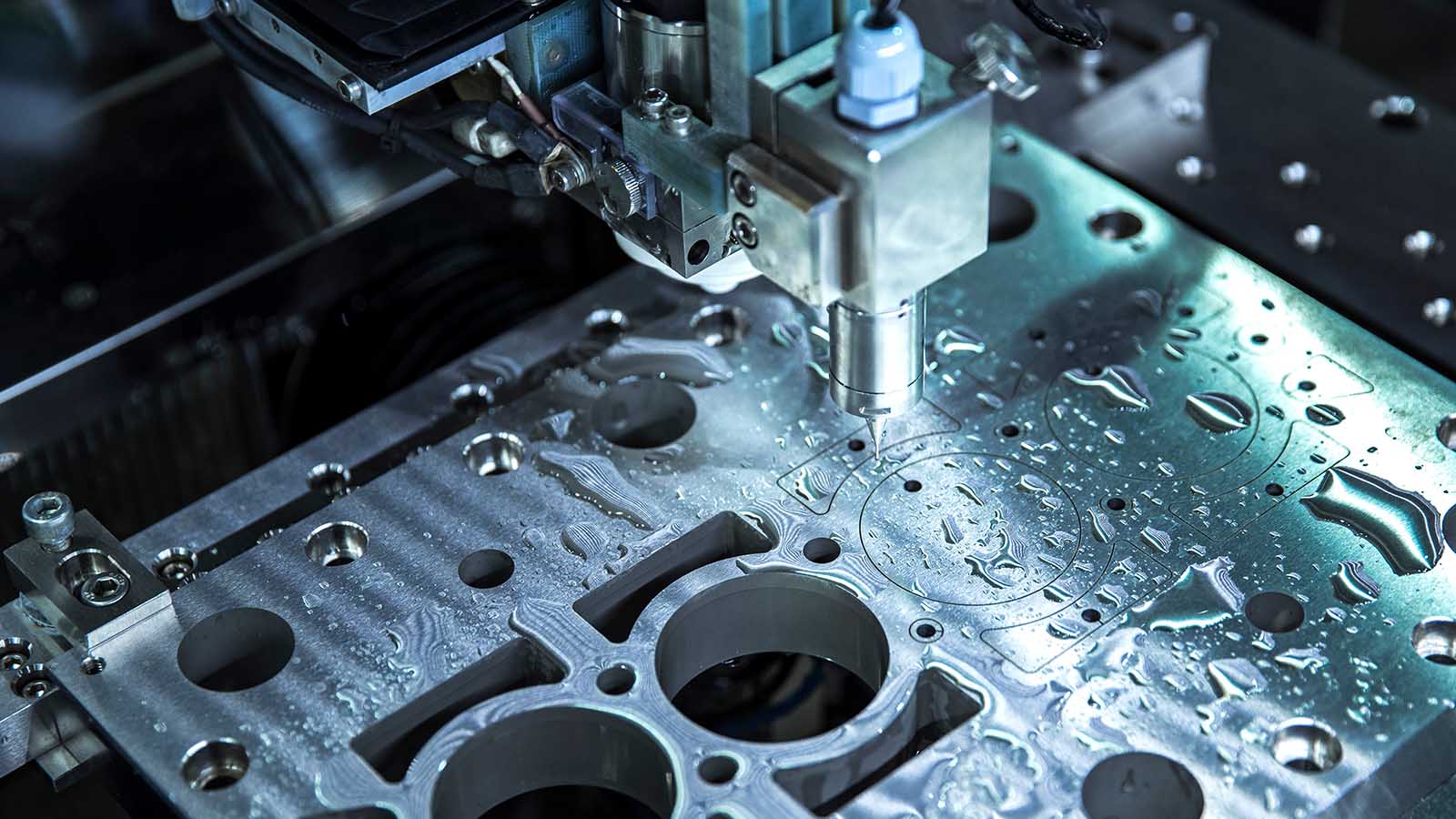

Precision Machining Methods for Efficiency

The elaborate layout demands of various fasteners necessitate using accuracy machining techniques for optimal performance in producing processes. Accuracy machining is essential in ensuring that bolts satisfy the precise requirements needed for their designated application. One of the key methods utilized in accuracy machining is Computer system Numerical Control (CNC) machining, which makes it possible for high degrees of accuracy and repeatability in the manufacturing of fasteners. CNC machines are capable of this content performing intricate cuts and shaping operations with marginal human treatment, leading to increased effectiveness and uniformity in the manufacturing process.

By using accuracy machining methods, suppliers can enhance the high quality of fasteners, lower product waste, and enhance total manufacturing effectiveness. The use of advanced machining processes assists make certain that bolts meet market standards and customer expectations for efficiency and integrity.

Variables Affecting Machining Process Performance

Numerous variables play a substantial function in identifying the performance of machining procedures in the manufacturing of fasteners. The very first essential aspect is the choice of reducing devices. Selecting the ideal tools based on the product being machined, wanted coating, and cutting rates can considerably influence the efficiency and high quality of the machining procedure. Furthermore, the reducing parameters such as cutting rate, feed rate, and deepness of cut are crucial variables that influence efficiency. Fasteners and Machining. Enhancing these parameters based on the details requirements of the fastener being generated is essential to attaining cost-effective and exact machining.

Machine strength and security additionally play a critical function in determining machining process efficiency. A well-informed driver can make real-time changes, troubleshoot problems successfully, and make sure that the machining procedure runs efficiently, eventually influencing the last high quality of the fastener.

Quality Assurance Actions in Production

Variables influencing machining procedure performance, such as reducing tool selection and machine stability, straight impact the execution of top quality control actions in manufacturing. Quality assurance actions are necessary in ensuring that products fulfill the called for requirements and requirements. In the production procedure, various methods are employed to preserve top quality requirements. Inspection and testing play a critical function in determining any kind of deviations from the desired end result. Normal maintenance of machining devices is additionally crucial to copyright quality control. Calibration of machines and tools is needed to make certain accurate and accurate manufacturing processes. Furthermore, implementing standardized operating treatments and procedures can assist in keeping uniformity and quality throughout the manufacturing line. Quality assurance determines not only focus on completion product yet additionally on every stage of the manufacturing process to avoid problems and mistakes. By sticking to rigid quality control actions, suppliers can enhance consumer satisfaction, build a reputation for integrity, Resources and inevitably accomplish optimum performance in their machining processes.

Verdict

To conclude, picking the ideal bolts and utilizing precision machining strategies are necessary for ideal performance in producing procedures. Comprehending the kinds and features of fasteners, in addition to factors affecting machining procedure efficiency, can result in go to this web-site enhanced effectiveness and high quality control actions. By taking notice of these details, manufacturers can attain higher degrees of efficiency and integrity in their items.

In the realm of engineering and production, the choice of fasteners and the ins and outs of machining processes play a pivotal role in determining the best efficiency and durability of an item (Fasteners and Machining). One of the key strategies utilized in precision machining is Computer system Numerical Control (CNC) machining, which makes it possible for high levels of precision and repeatability in the production of fasteners. The use of innovative machining procedures assists ensure that fasteners satisfy industry standards and customer assumptions for efficiency and integrity

In final thought, choosing the ideal fasteners and utilizing precision machining techniques are essential for ideal performance in producing procedures. Comprehending the types and qualities of bolts, along with aspects affecting machining procedure performance, can lead to enhanced efficiency and top quality control procedures.

Report this page